Unionville High School Building Statistics

Building Statistics Part 2

Unionville High School Additions and Renovations

Michael Beam | Construction Option | September 5th 2011

|

Primary Engineering Systems Data |

|

Construction |

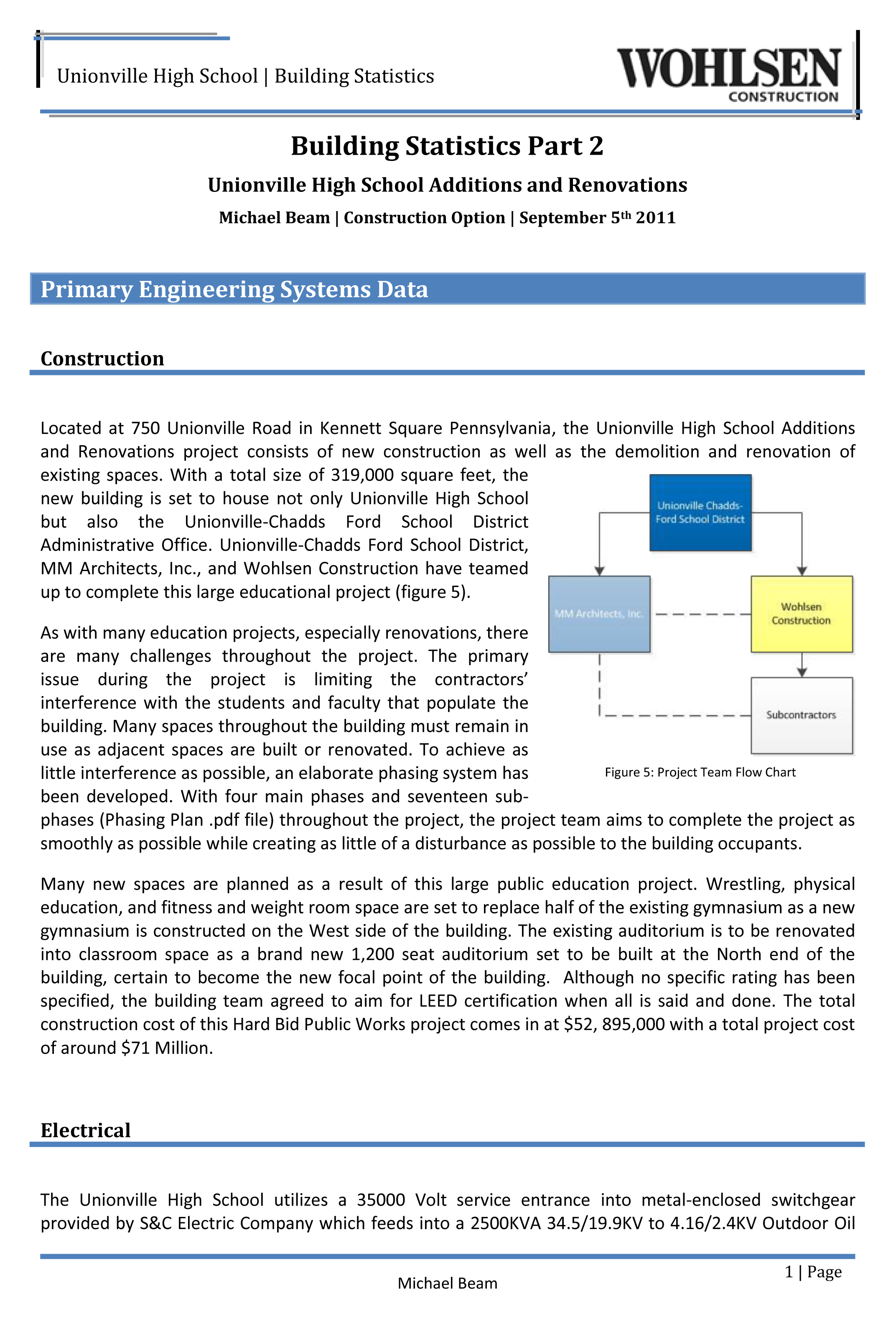

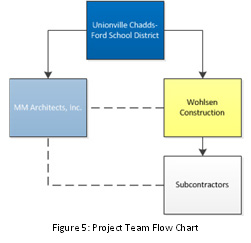

Located at 750 Unionville Road in Kennett Square

Pennsylvania, the Unionville High School Additions and Renovations project consists

of new construction as well as the demolition and renovation of existing

spaces. With a total size of 319,000 square feet, the new building is set to

house not only Unionville High School but also the Unionville-Chadds Ford

School District Administrative Office. Unionville-Chadds Ford School District,

MM Architects, Inc., and Wohlsen Construction have teamed up to complete this

large educational project (figure 5).

Located at 750 Unionville Road in Kennett Square

Pennsylvania, the Unionville High School Additions and Renovations project consists

of new construction as well as the demolition and renovation of existing

spaces. With a total size of 319,000 square feet, the new building is set to

house not only Unionville High School but also the Unionville-Chadds Ford

School District Administrative Office. Unionville-Chadds Ford School District,

MM Architects, Inc., and Wohlsen Construction have teamed up to complete this

large educational project (figure 5).

As with many education projects, especially renovations, there are many challenges throughout the project. The primary issue during the project is limiting the contractors' interference with the students and faculty that populate the building. Many spaces throughout the building must remain in use as adjacent spaces are built or renovated. To achieve as little interference as possible, an elaborate phasing system has been developed. With four main phases and seventeen sub-phases (Phasing Plan .pdf file) throughout the project, the project team aims to complete the project as smoothly as possible while creating as little of a disturbance as possible to the building occupants.

Many new spaces are planned as a result of this large public education project. Wrestling, physical education, and fitness and weight room space are set to replace half of the existing gymnasium as a new gymnasium is constructed on the West side of the building. The existing auditorium is to be renovated into classroom space as a brand new 1,200 seat auditorium set to be built at the North end of the building, certain to become the new focal point of the building. Although no specific rating has been specified, the building team agreed to aim for LEED certification when all is said and done. The total construction cost of this Hard Bid Public Works project comes in at $52, 895,000 with a total project cost of around $71 Million.

|

Electrical |

The Unionville High School utilizes a 35000 Volt service entrance into metal-enclosed switchgear provided by S&C Electric Company which feeds into a 2500KVA 34.5/19.9KV to 4.16/2.4KV Outdoor Oil Filled Transformer, through a metering station, and finally into a 1500KVA Oil Filled Transformer with a 4160 Volt, 3 Phase primary, and a 480/277V, 3 phase, 4 wire Y transformer secondary. Due to the varying uses throughout the building, both 480/277V and 280/120V service is used throughout the building. All of the lighting within the building is serviced by 480/277V, 3 phase power as well as all blower coil units (BCU) and air handling units (AHU). All equipment used in the shop is fed with 480/277V power, while kitchen equipment and other miscellaneous items run on 208/120V power.

|

Lighting |

Many different fixtures are used throughout the building

based on which area they are serving. Classrooms are designed using a 2' x 4'

recessed fixture with a fluorescent troffer and an acrylic diffuser, utilizing a

2, 3, or 4 lamp electronic ballasts (figure 6). 2' x 4' recessed fixtures are

also used in the corridors of the buildings, although each fixture used in the

corridor uses just two lamps. All 2'x'4 recessed fluorescent fixtures,

classroom and corridor alike, utilize F32T8 lamps. Almost every classroom and

restroom is designed with occupancy sensors in order to cut down on unnecessary

use of electricity.

Many different fixtures are used throughout the building

based on which area they are serving. Classrooms are designed using a 2' x 4'

recessed fixture with a fluorescent troffer and an acrylic diffuser, utilizing a

2, 3, or 4 lamp electronic ballasts (figure 6). 2' x 4' recessed fixtures are

also used in the corridors of the buildings, although each fixture used in the

corridor uses just two lamps. All 2'x'4 recessed fluorescent fixtures,

classroom and corridor alike, utilize F32T8 lamps. Almost every classroom and

restroom is designed with occupancy sensors in order to cut down on unnecessary

use of electricity.

With a brand new auditorium comes a state of the art lighting system. The main lighting system for the auditorium uses a 9" diameter x 16" long metal cylindrical fixture. Both Metal Halide and Fluorescent lamps are used with this fixture type using Q500 T4 or 70W MH in the front and majority of the auditorium, or Q250 T4 or 50W MH lamps above the balcony towards the back of the balcony. Two different fixture types (research ongoing) are designed to be mounted on the three catwalks and will be utilized to illuminate the stage during use.

|

Mechanical |

With 319,000 square feet to condition, the Unionville High School Building utilizes 22 Air Handling Units, 4 existing and 18 new. The 4 existing units as well as 15 of the new AHU's are located on the roof, with the remaining 3 new units housed in mechanical rooms within the building. All standard classrooms loads are handles by Innovent Laser Dedicated Outside Air Systems (DOAS), with supply fan loads ranging from 5,500 to 9,900 CFM. The auditorium is supplied completely by one unit, an Innovent RHXC Single Zone Heat Recovery VAV Unit with a max supply fan load of 26,000 CFM. Another single zone heat recovery system is used in the Gymnasium, with an Innovent 5000 VAV unit supplying a maximum of 32,000 CFM. In total 11 DOAS, 2 combination DOAS/VAV, 7 VAV, and 2 CAV units are to be used to service the building.

A total of 10 Blower Coil Units service the building as well, all of which are provided by Trane. Each 4 pipe BCU uses interlocks with a specific AHU and services multiple locations. The maximum loading capacity of the air sides of the units range from 300 to 2,770 CFM, while the cooling coil system loads range from 1.0 to 7.0 GPM and the heat coil loads range from 1.0 to 4.5 GPM. Finally, Vulcan DV-412 baseboard radiators have been used in several locations, generally some of the smaller spaces within the school including special education classrooms and personal offices. Each radiator is to be installed 4" from the top of the finished floor and is designed to handle a capacity of 5,400, 9,000, or 15,300 (corridor) BTU load depending on the space.

Structural |

Several types of structural elements are to be incorporated in the new Unionville High School Building. The primary foundation system uses several types and sizes of structural steel columns in tandem with reinforced concrete piers and footers, a 4" concrete slab on grade on top of 4" of crushed stone, and 16" CMU block for the foundation walls. Although primarily made up of W-flange columns, several locations throughout the foundation system utilize hollow structural steel members. HSS8x8x1/2 columns are used on the Western side of the building, while W10x33 and W14x90 are the two most prevalent w-flange sizes used in the foundation system. In most areas, the steel columns and CMU block walls run more than one story and make up the structure for exterior walls for the building. Reinforced concrete piers designed to carry the load of the columns range from 1'10" x 1'10" to 3'0" x 1'10" in size. There are several sizes of strip footings using primarily #5 rebar as well as various column spread footing sizes using #4, #6, and #8 rebar.

The upper floors of the building utilize a structural steel skeleton system composed almost entirely of W-flange beams, primarily W10, W14, W18, and W21 members. In the instance of an elevator shaft, however, 8" CMU block is to make up the structure for the wall. Due to the multiple elevations of the land on site, several types of flooring systems have been designed. A 4" slab on grade on top of 4" crushed rock serves as the flooring system for the portion of the building sitting on soil, while a concrete on metal deck system is to be used when an area is above a preceding floor.

A variety of roofing systems are to be used throughout the

building, depending on the area. Due to the large spa n and the barreled roof

design, 48LH13joists have been chosen as the structure for the auditorium

roof. Each joist has 8 foot wide bays, a curved top chord, and a 7 ½" height

between the seat and the bottom chord. The new gymnasium will feature a similar

roofing system, utilizing W10x39 truss with a curved top chord.

n and the barreled roof

design, 48LH13joists have been chosen as the structure for the auditorium

roof. Each joist has 8 foot wide bays, a curved top chord, and a 7 ½" height

between the seat and the bottom chord. The new gymnasium will feature a similar

roofing system, utilizing W10x39 truss with a curved top chord.

Note: All non-sited photographs and figures were created by myself, Michael Beam.